Decoral Process

In 1993 we invented a technology to decorate metal surfaces which is based on the chemical-physical process of sublimation.

Aluminium sheets, profiles or 3D objects are powder coated and then decorated using a heat-transfer film printed with special inks.

This way you get decorative finishes that reproduce natural materials like woodgrain, marble, corten and whatever image on the aluminium support.

Decorated products can be certified for outdoor use.

Pre-treatment

The pre-treatment is aimed at cleaning and protecting the metal surface from corrosion and weathering. It is a necessary stage for preparing the metal substrate and ensuring a high quality powder coating.

Powder coating

The pre-treated metal substrate is powder coated using electrostatic guns. Then, it is cured in the oven according to the specifications of the technical data sheet. The base coat protects the product against factors such as weather, corrosion and abrasion.

Our powder coatings, made of polyester or polyurethane resins, are totally free of solvents and heavy metals.

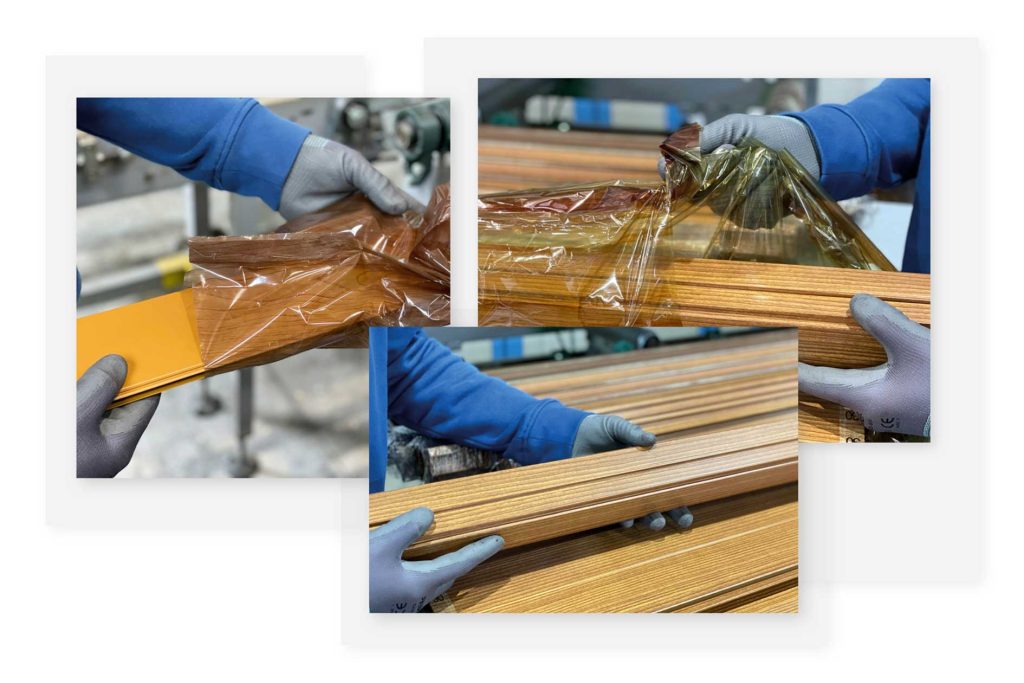

Decoration

The object to be decorated is wrapped using a heat-transfer film printed with the decorative pattern. Subsequently, it is vacuum sealed to the surface and placed inside a Decoral® oven where, through heat and pressure, the inks printed on the film are transferred into the coating layer. A few minutes later, it is taken out of the machinery and the exhausted film is removed to reveal the decorative pattern.

Final result

Get the finish you prefer on any kind of product: lighting, handrail, furniture, flooring, fencing, shutter, signage, advertising object and so on.