Savoir-faire.

Vous pouvez compter sur les ressources que nous proposons: peintures en poudre, films de transfert à chauc et machines de décoration.

Processus Decoral

In 1993, Decoral® invented and patented a unique sublimation process for decorating metal surfaces. Raw aluminium sheets, profiles or 3D objects are transformed into surfaces that replicate the natural look of woodgrain, marble, corten, or custom patterns.

This technology applies mainly to aluminium and steel, but also to other materials resistant to 200°C. Results are certified for outdoor use, ensuring both aesthetic quality and technical performance.

Qualité

In 2012, Decoral® introduced QualityDecoral®, an in-house certification providing measurable data on the durability and outdoor performance of our finishes. The concept was born after our R&D team observed how harsh climates—such as Florida’s—affected the color and gloss of coated surfaces. We decided to put our coatings to the test under these extreme conditions. The results were remarkable: even after five years of natural exposure, our finishes maintained their color, gloss, and protective properties. Today, QualityDecoral® stands as a guarantee of long-lasting performance, trusted by architects and manufacturers worldwide.

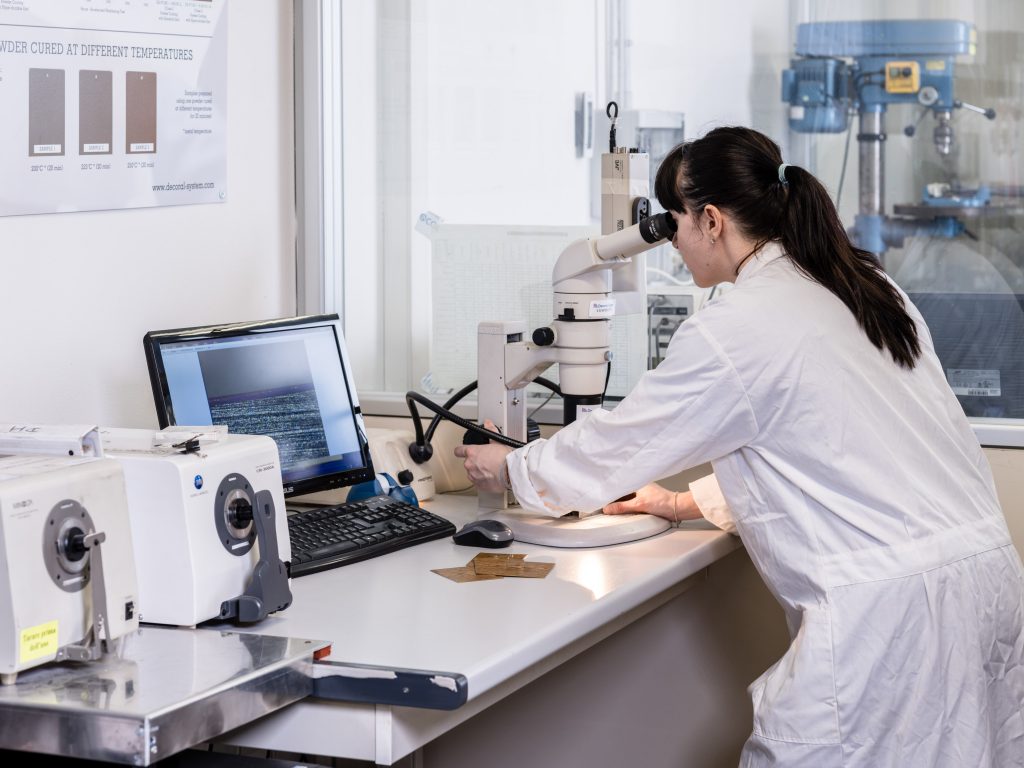

Laboratoire Décoral

The heart of Decoral® is Decoral Lab, our in-house research and testing center. Here, every finish undergoes rigorous laboratory tests to ensure durability, color uniformity and resistance to weathering. Our R&D team is focused on developing eco-friendly, solvent-free coatings that meet both design and environmental standards, helping projects achieve major sustainability certifications.